Truck diagnostic tools are specialized electronic devices and software used to monitor, analyze, and troubleshoot issues within a truck’s complex mechanical and electronic systems. They connect to the vehicle’s onboard diagnostics (OBD) port or other specific connectors to gather real-time data from various Electronic Control Units (ECUs).

How They Work

The tools function by interpreting data and trouble codes generated by the truck’s internal computers. The general process involves:

Data Collection: Sensors throughout the vehicle (engine, transmission, brakes, etc.) send data to the ECUs.

Data Transmission: The diagnostic tool connects to the vehicle, often via wired or wireless (Bluetooth/Wi-Fi) connection, to extract this data and any stored fault codes.

Data Analysis: The accompanying software translates these codes into understandable information about potential problems, often providing guided troubleshooting steps.

Actionable Insights: Technicians use this information to pinpoint the precise location and nature of faults, enabling quicker and more accurate repairs.

Types and Features

Diagnostic tools for trucks range in complexity and functionality:

Basic Code Readers: These affordable, portable devices simply display trouble codes, requiring the user to research the meaning of the code externally.

Advanced Diagnostic Scanners: These more sophisticated systems offer extensive features such as:

Bi-directional control: The ability to perform critical commanded tests (e.g., manually regenerating a diesel particulate filter or injector cut-out tests).

Live Data Monitoring: Displaying real-time performance data and comparing it against known good measurements.

ECU Programming/Coding: Reprogramming or recalibrating control units after repairs or part replacements.

Integrated Technical Information: Providing access to wiring diagrams, technical bulletins, and repair guides.

Benefits

The use of these tools is crucial for modern truck maintenance, offering several benefits:

Reduced Downtime: Quick and accurate problem identification minimizes time spent on troubleshooting and repairs.

Preventive Maintenance: Identifying issues early helps prevent major breakdowns and extends the lifespan of the vehicle.

Cost-Effectiveness: Pinpointing problems precisely avoids unnecessary parts replacements and labor costs.

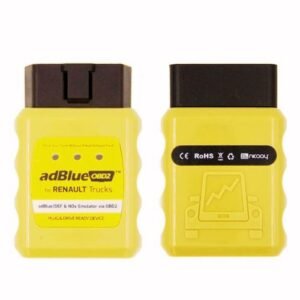

Safety and Compliance: Ensures that critical systems, such as brakes and emissions controls (AdBlue/SCR systems), are operating safely and in compliance with regulations.

Key Manufacturers

Major companies offering comprehensive solutions include:

Launch

Xpro5

Thinkcar

Autel

Gscan

Fcar

zenith

Diagzone

Humzor

ISSBD

JDTCL

Trucks Explorer

Bosch

Snap-on

Jaltest (Cojali)

TEXA